Air Separation Gas Plant Spares

Oxyplants India Pvt Ltd are manufacturer & Exporter of Oxygen Gas Plant Equipment's and Spare parts for Allied Machineries. We are a reputed and esteemed supplier of spare parts for Oxygen Gas Plants in India as well as overseas. Our products include wide range of Spares parts for Oxygen Gas Plants.

AIR COMPRESSOROxyplants India Pvt Ltd supplies air compressors used in oxygen gas plants. It is a double acting multi stage horizontal cross head type built in one, two or three rows. The compressor is driven by electric motor through V-belts or direct drive .Air compressor has inter coolers between two stage. The discharge pressure in this air compressor is 35-40 Kgs/Cm² depending on the plant condition and requirements.

Oxyplants Supply complete range of Spare Parts for Reciprocating Air Compressors like Ingersoll Rand & Kirloskar Pneumatic. We supply all Spears like.

- Suction Filter

- Oil Filter

- Gaskets

- Drain Valves

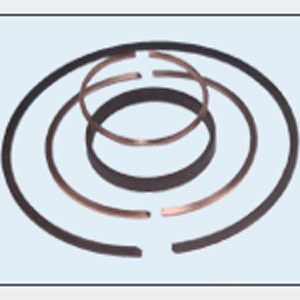

- Piston Rings

- Gland packings

- Piston

- Piston Rod

- Cylinder Block

- Gland packing assembly

- Tube BUNDLES of inter coolers.

- Main Bearing Housing

- Crank case assembly complete with crank shaft

- CONNECTING rod and bearings as per the requirement.

- 1st, 2nd, 3rd and 4th stage suction & discharge valve having integral parts such as channel springs etc.

CHILLING UNITS

Freon based Industrial Refrigerant type Chilling Unit With Thermostatic Cooling Coils. Chilling Water Tank with 2 Air Coils for Cooling of the process Air to 10 Deg. C to 12 Deg. C before it Enters Molecular Sieve Battery and longevity of the Molecular Sieves. With air coils fitted inside of circular tank with cover and base mounted on the skid. This unit has got a Freon evaporation coils fitted inside the tank with inlet and outlet connections connected to a Freon unit of packaged type design with sealed compressors Copland Make, Danfoss Controls Expansion valve and digital indicator. Factory fitted on skid with pipelines.

We Supply Complete Range of Spares for Chilling Unit.

MOLECULAR SIEVES BATTERY

The Cold air from the cascade cooler & chilling tank is partly free from moisture, Oil & Oil Vapors. The separation of moisture is carried out in different stages so that the air entering in the molecular sieve battery has minimum moisture level & better adsorption of CO² can take place. The Molecular Sieve Battery thus completely removes the moisture & CO² from the air passing through it. If the battery does not function efficiently the moisture & CO² will enter into Air Separation Column and Moisture will become Ice & CO² will become Dry Ice form which will choke the Expansion Valves, heat exchanger tubes and other equipment's resulting in the stoppage of the Plant.

We Supply Complete Range of Spares for Molecular Sieves Battery including:- Air Inlet & Outlet Valves.( Globe valve ( ND64) with SS Special seating )

- Nitrogen Inlet & Outlet Valves. .( Globe valve ( ND64) with SS Special seating )

- Molecular sieve & Activated alumina.

- Needle Valves for Pressurizing & de-pressurizing lines.

- Electric heating element for Battery heaters.

- Terminals for Battery Heater.

- Temperature Gauges.

- Pressure Gauges.

- Temperature Sensors.

- Equalizer Valves.

- Butterfly Control Valves.

Liquid Oxygen Pump

It is a single acting, Single Cylinder, Horizontal Type, Non Lubricated, Reciprocating Pump, Pumps liquid Oxygen & gasifies in heat exchangers for final filling as gas in cylinders at a pressure of 150 kg/cm2 g.

Liquid Oxygen Pump when is Started, the liquid oxygen from the main condenser enters the outer jacket of the pump. Some of this liquid evaporates due to heat produced in pumping and the vapour is passed to the upper column as gas. The major part of liquid oxygen is taken into the pump cylinder and then compressed out by the piston Forward stroke. This high pressure liquid oxygen passes through two non-return valves into the heat exchangers, Gasified and filled in to cylinders through Filling Manifolds.

We supply Complete Range of Spares for LOX Pump of all capacities are per customers requirement including

- S.S. Liner (Size- 20mm to 44mm)

- S.S. Piston (Size- 20mm to 44 mm)

- Piston Rings, Guide Ring & Expander Rings.

- Cross head

- Gland Packing

- Safety valves

- Crank shaft

- Oil Wiper Rings.

- Oil Seals.

- Non-Return Valves of sizes 1/2″, 5/8″ & 3/4″

- Connecting rod with bearings.

- Gudgen Pins.

- Brass Gland Nut & Cylinder Head Nut

Liquid Nitrogen Pump

It is a single acting, Single Cylinder, Horizontal Type, Non Lubricated, Reciprocating Pump, Pumps liquid Nitrogen & gasifies in heat exchangers for final filling as gas in cylinders at a pressure of 150 kg/cm2 g.

Liquid Nitrogen Pump when is Started, the liquid Nitrogen from the condenser bottom cone enters the outer jacket of the pump. Some of this liquid evaporates due to heat produced in pumping and the vapour is passed to the upper column as gas. The major part of liquid Nitrogen is taken into the pump cylinder and then compressed out by the piston Forward stroke. This high pressure liquid Nitrogen passes through two non-return valves into the heat exchangers, Gasified and filled in to cylinders through Filling Manifolds.

We supply Complete Range of Spares for LOX Pump of all capacities are per customers requirement including

- S.S. Liner (Size- 20mm to 44mm)

- S.S. Piston (Size- 20mm to 44 mm)

- Piston Rings, Guide Ring & Expander Rings.

- Cross head

- Gland Packing

- Safety valves

- Crank shaft

- Oil Wiper Rings.

- Oil Seals.

- Non-Return Valves of sizes 1/2″, 5/8″ & 3/4″v

- Connecting rod with bearings.

- Gugen Pins.

- Brass Gland Nut & Cylinder Head Nut

Air Separation Column (Cold Box)

Air separation column (cold box) consists of outer steel casing, Main heat exchangers, Bottom column, Top column, Condensor, Sub-coolers, Liquid nitrogen Tank. Expansion Valves, Drain & Analysis Valves, Niddle Valves Insulation material, Digital electronic temperature indicator & scanner, PT 100 sensors, Differential Pressure level Indicator.

The expanded air leaving from the Expansion Engine & Air Expansion valve enters Air Separation Unit. The rich liquid containing Oxygen & Nitrogen is collected in Lower column having more than 40% O². The rich liquid from the lower column is taken to the upper column through RL Expansion Valve. The Poor Liquid (PL) collected on the bottom cone of Condensor is taken to upper column through PL Expansion Valves in this process pressure is dropped 4.5 kg/Cm² to 0.5kg/Cm² g in upper column . The Nitrogen being more volatile come out and oxygen getting condensed and collected in condenser from where it is pumped by LO²/LIN Pump in to cylinders.

- Temperature Scanner

- Liquid Level Gauge

- RTD Sensor

- Pressure Gauges

- Expansion valves

- Needle Valves.

- Drain & Analysis's Valve.

- Perlite Powder

- Top Column safety Valves --(0.65 Kg/Cm²)

- Bottom Column safety valve – (6.5 kg/Cm² )

- High Pressure Safety Valves – ( 165 Kg/Cm² )

Expansion Engine

The Expansion Engine is vertical Single/Double Cylinder, Dry Running, Reciprocating type engine and plays most important role in cooling of air. The air enters the Expansion Engine where it is expanded from 40 kg/Cm² to 5 kg/Cm² where the temperature drops to –1500 ℃ Up to –1750 ℃ This produces the cold required for the plant.

We supply Complete Range of Spares for Single/Double Acting Expansion Engines of all capacities are per customers requirement including

- Cylinder Head.

- Piston ( 70 MM – 90 MM)

- Piston Ring Set (Guide Ring & Expander Ring Set )

- Cross Head

- Gudgen Pins.

- Crank shaft

- Push Pump

- Puppet Valve

- Cam Set

- Oil Pump

- Oil Seals

- Oil Filters.

- Oil Wiper.

- Ball Valve Assembly

- Push Rods & its Springs

- Teflon Piston Rings

- Valve Block & its integral parts

- Inlet/Outlet Valves

- Small End & Big End Bush Bearings.

Online Purity Analyzers

We offer online, digital, electronic analyzers with mounting & portable type for monitoring purities of Oxygen, Nitrogen, Argon and other gases. This indicator is a convenient and handy instrument for field applications where a quick, easy and accurate measurement of purity of oxygen is required. The sensor being located within the instrument, requires the gas sample to be delivered to inlet port. This instrument is ideal where the sample is available at a slight positive pressure.

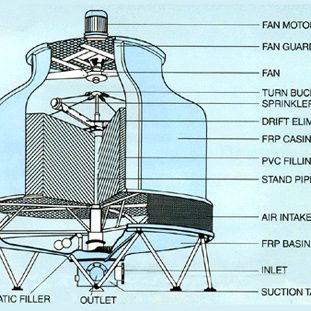

Cooling Tower

Induced Draft-Rotary Sprinkler type with Aluminum Casting Fan, FRP Body with suitable Electric Motor3 HP / 960 RPM for maintaining the circulating water temperature for optimum performance of the Plant. Different capacities from 500 LPM to 1500 LPM.

Oxygen/Nitrogen Filling Manifolds

For filling high-pressure gas Oxygen/Nitrogen into gas Cylinders. The filling connections are Teflon reinforced with stainless Steel wire breaded flexible high pressure hoses.

We supply Complete Range of Spares for Oxygen/Nitrogen per customers requirement including

- Cylinder Valves

- Manifold Valves

- Safety valves

- Pressure Gauges

- SS Tubes for Pig Tail Connection

- Brass Bull Nose & Nuts